MACHINES FOR GRAPEVINE NURSERIES

A FULL RANGE OF MACHINES

For more than 38 years, BM emballage has been developing machines for your profession, due to a great listening and collaboration with its wine-nursery costumers.

Our machines, developed with a constant focus on improvement, benefiting from knowledge and experience, allowing us to offer perfectly and durable solutions at a higher technical level.

At each stage of the business, we bring an answer to the stock nurseries wood treatments, the grafts and rootstocks or seedlings mechanization needs – with robustness, accuracy, reliability and ease of use.

Which is for you the opportunity to :

- increase your company independance considering the recruiting difficulties and increasingly unskilled labour

- save time by mechanizing the most time-consuming tasks traditionally performed manually

- reduce the strain at work while significantly improving productivity

- optimize the raw material

- increase your competitivness

SEE OUR MACHINES

From the rootstock disbudding or pruning , to the rootstock or scion cutting to the bundle preparation :

- DISBUDDING

> BM6 – Pruning

> BM8 – Disbudding

- GRAFTING

> BMGΩ – Grafting rootstocks and scions

- TYING

> B18P – Strapping

PRUNING MACHINE

Up to 4 times faster than manually, the BM6, a pruning machine, allows you a complete treatment in a single operation while combining comfort of use and ease of maintenance.

- High performance

- Simple adjustment and maintenance

- New cutting head

- New drive system

DISBUDDING MACHINE

Two actions made possible in a single operation, this rootstock disbudding machine improves yield and reliability compared to manual processing.

- Improved efficiency and reliability compared to manual processing

- Integral housing protection for safe, clean and quiet operation

- Automatic blade cleaning by blowing and mechanical action

- Independent modules design for quick maintenance

CUTTING ROOTSTOCK MACHINE

With a touch screen for parameter setting and operations management, the BM116 offers a controlled and efficient production “cutting, sorting and counting” in a single process.

- Up to 116 rootstock per minute

- About 98% of success rate for the handled effective lengthes

- The rootstocks exit and the bundles realization are placed on the machine end, on a double gutter, for an optimized production

- Less than 20 % falls, garanteed

CUTTING SCION MACHINE – SPEED

BM76S

Allowing the cutting of pre-cleaned branches, the BM76S offers the guarantee of great reliability with a performance up to 8000 compliant scions per hour.

- About 133 scions per minute, conforming scions, calibered by diameter and length, including the internode cut, resulting in 2 cuts per scion.

- Only 1 operator per machine

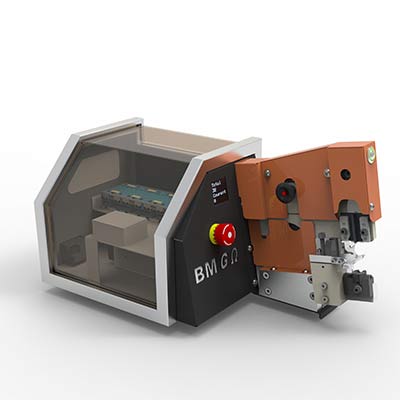

GRAFTING MACHINE

BMGΩ

BMGΩ grafts rootstocks and scions

- Cutting unit powered by an electric motor, preserving

operators’ physical integrity. - Prevention of any risk of injury by detection of glove contact with the blade.

- Extremely quiet machine, reducing workload.

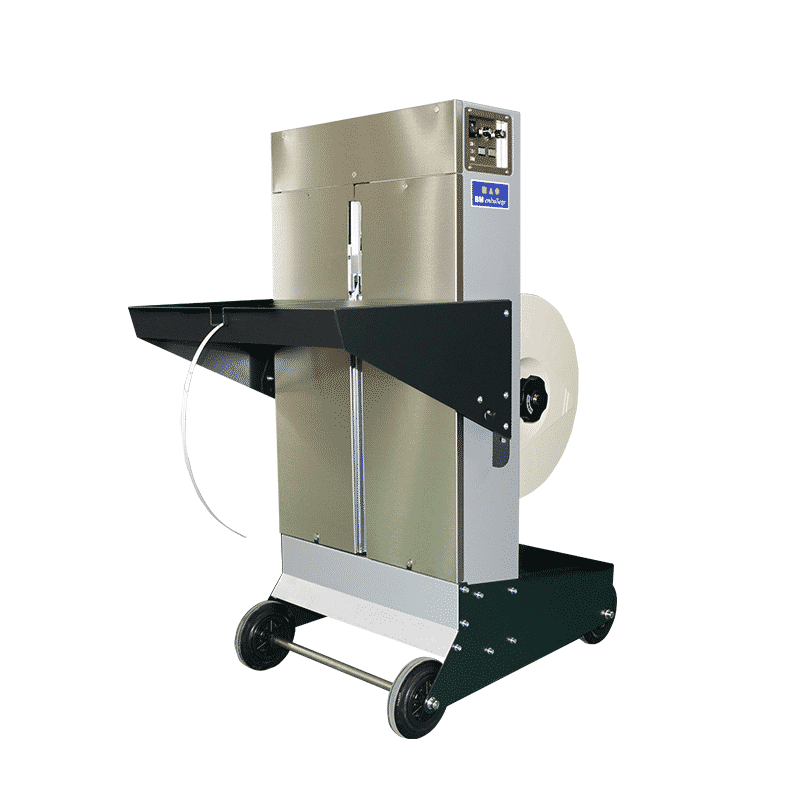

SEMI-AUTOMATIC STRAPPING MACHINE

B18P

Specially designed to operate in rough environments, the B18P strapping machine efficiently and quickly gathers wood, meters, rootstocks, grafts and vine plants for optimized bundles preparation.

- Reliable machine

- Maintenance free (no belts)

- Fast heat

For any request, quotation and information,

do not hesitate to contact our advisors.